Main function of Sleepers

• Holding rails to correct gauge and alignment.

• Firm and even support to rails.

• Transferring the load evenly from rails to wider area of ballast.

• Elastic medium between rails and ballast.

• Providing longitudinal and lateral stability.

Ideal Requirements of Sleepers

1. It should provide easy means of maintainability.

2. Handling of rails sleepers and fastening should be easy.

3. Quick restoration after accident is possible.

4. Material and design is available.

5. It should have anti-theft and anti-sabotage quality.

6. It should be overall cheap.

7. It should be fit for track circuiting.

8. The base area of sleeper should be sufficient to prevent crushing of ballast.

Types of Sleeper

Commonly used sleepers in Indian railway are as follows:

1. Wooden Sleepers

2.Cast Iron Sleepers

3. Steel Sleepers.

4. Concrete Sleepers

Wooden Sleepers:

Description of Wooden Sleeper

Size of wooden sleepers in mm:B.G.: For ordinary track 2750 x 250 x 130

Durable and non durable types of sleepers. Life of Sleeper:

Durable –19 years (B.G.)/ 31 years (M.G.) Non-Durable- 12 to16 years.

Advantages

• Easy to manufacture and handling.

• Suitable for track circuited area.

• Can be used with or without ballast.

• Suitable for bridges, Points/Crossings.

• Suitable for gauntleted track.

• Alignment can be easily corrected.

Disadvantages:

• Lesser life.

• Liable to damage by beater packing.

• Difficult to maintain the gauge.

• Susceptible to fire hazards.

Cast Iron Sleepers:

CST-9 sleeper is combination of pot, plate and box and it is 9th trial approved by Central Standard Trial Committee. Two CST-9 plates are joint by a tie bar using 4 quarters. Gauge adjustment of -5mm to +5mm is possible. T-478 (M) and T-443 are two types of CST-9 sleepers. Later it is known as Anti-Sabotage sleeper. Three numbers anti-sabotage sleepers are used per rail/panel out of which 2 at the shoulder and 1 at the centre. It is also known as Reverse Jaw CST-9 Sleeper. Weight of CST-9 sleeper is approximate 102 Kg for B.G. and 58 Kg for M.G.

Precautions during working on CST-9 sleeper track:

1. All part of CST-9 plate should be packed equally. Cracked and weak sleepers should not be covered by ballast.

2. Tie bar should be treated once in 5 to 7 years to avoid corrosion and rusting of

tie bars.

3. Liners and over size keys should be used to maintain worn out track.

4. 1.8 Kg keying hammer should be used. Beater should not be used for applying

and removing keys.

5. Quarter should be applied correctly keeping tapered portion towards CST-9 plates.

6. Pad plates and Saddle plates of correct thickness should be used to prevent creep on worn out rail seat.

Advantages of Cast Iron Sleepers:

1. Lesser corrosion.

2. Easy handling due to light weight.

3. Higher Scrap value.

Disadvantages of Cast Iron Sleepers:

1. Not suitable for high speed route.

2. Difficult to maintain the Gauge.

3. Lesser lateral stability.

4. Not fit for track circuited area.

5. Not suitable for mechanical maintenance.

6. Tie bars weakened by corrosion.

Steel Trough Sleeper

Types of S.T. Sleepers

1. ST sleepers with Pressed up lugs.

2. ST Sleepers with loose jaws.

3. Bolt and clip type ST Sleepers.

4. Special ST Sleepers for Turn out.

5. ST Sleepers with pad plates for use with elastic rail clip.

Advantages of ST Sleepers:

1. Longer life

2. Better Stability

3. Lesser damage during handling /Transport

4. Easy to maintain Gauge

5. Simple Manufacturing Process

6. High Scrap value

Disadvantages of ST Sleepers:

1. Liable for corrosion.

2. Not fit for track circuited area.

3. Develops cracks at rail seat during service.

4. Can only be used for rails for which it is manufactured.

Adzing of Sleepers –

1. When wooden sleepers are used without bearing plates, the rail seats should be

adzed to a slope of 1 to 20, planed for the section of the rail with the correct template. It is desirable to accommodate the rail foot in a recess 3 to 5mm. deep in the adzed portion of the sleeper to restrict the lateral forces being transmitted to the spike and to protect the sleeper from getting spike killed. The operation of adzing and recess cutting should be carried out preferably in the track conditioning depot, where the adzed rail seat may be treated with coal tar/creosote.

2. For treated sleepers adzing and recess cutting should be done before treatment.

3. Sleepers should not be adzed in the case of points and crossings.

4. When bearing plate or chairs are used it should be ensured that the seat is adzed or planed to ensure even bearing and that the two bearing areas are truly in the same horizontal plane.

Auguring of Sleepers –

1. Spike holes should be bored right through the sleeper vertically where bearing plates are used and at right angles to the rail seat where the rail rests directly on the sleeper.

2. The size of augur for boring should be as given below:

3. For ‘T’ category sleepers boring should be done before treatment.

4. When extracting dog spikes, the fulcrum on which the crow bar works should be raised so that the spikes can be withdrawn vertically without enlarging the dog spike hole.

5. Plate/Rail screws should always be screwed by box spanners and not driven by

hammers.

Use of Bearing Plates :–

a. Bearing plates should be provided invariably on ‘T’ category sleepers.

b. They should be compulsorily used in the following locations :

1. All sleepers on girder bridges.

2. All sleepers of turn outs.

3. All timbers of ash pits and examination pits.

4. All joint sleepers.

5. On sharp curves of radius less than 600m. on B.G. and M.G.

c. Bearing plates should receive two coats of black oil prior to their being fixed to the sleepers.

Screws/Spikes at Rail Seat –

(a) The number of spikes/screws per rail seat should be as given below :–

1. All joint sleepers, bridge timbers,

turn out sleepers and ash pit timbers Four

2. Intermediate sleepers on curves on three

other than branch line (Two out side&one inside)

3. Intermediate sleepers on curves on Two(One inside &

branch lines and on straights One outside).

(b) Where A.C. bearing plates are used on intermediate sleepers for arresting creep the number of screws/spikes per plate should be four for B.G. and three for M.G.

(c) 1. When two screws/spikes are used, the outer ones should be in line on one side and the inner ones on the other side of the centre line of the sleeper.

2.Screws/Dog spikes should be dipped in coal tar before use. If it is necessary to draw and re-drive spikes or to drive spikes in holes other than those freshly bored, such spike holes should first be carefully plugged with tightly fitting tarred wooden plugs and re-bored before spikes are driven.

3.Additional screws/spikes may be provided at the discretion of Chief Engineer wherever necessary.

Reconditioning of Wooden Sleepers –

(a) Reconditioning of all released wooden sleepers before their reuse should be carried out in a centralized depot. To arrest deterioration in track, systematic practice of reconditioning ‘in-situ’, the spike killed sleepers, otherwise in good condition, should be resorted to.

(b) Procedure for Plugging Spike killed Sleepers ‘in-situ’ - Sleepers without bearing plate can be reconditioned without removing the sleepers from track.

The sequence of operations should be as under:

(i) The fastenings viz. spikes, screws etc. are removed and the sleeper shall be cleaned of all dust.

(ii) The existing holes should be re-bored so as to ensure that the existing holes are adequately scrapped all round.

(iii) The re-bored and cleaned spike holes shall be plugged using tapered octagonal plugs of size of slightly bigger than the holes. These plugs are made from scrap hard wood sleepers in a centralized depot.

(iv) Before driving the plugs, the plugs are dipped in a mixture of creosote and coal tar. The plug should be driven right upto the bottom of the holes.

(v) After plugging, a new hole would be bored at some distance in line with the old holes, parallel to the centre line of the track. Then sleeper fastenings are reinserted in new holes.

(c) Procedure for reconditioning of released wooden sleepers in Permanent Way Depots. In the case of sleepers with bearing plates, repairs to spike killed holes which would involve removal of the sleeper from the track for the purpose of plugging the existing holes, re-adzing of the rail seat and boring holes in new position are best carried out in a centralized depot.

When reconditioning of sleepers is done in a depot, the following works are also carried out:-

(i) End binding;

(ii) Re-adzing of rail seat;

(iii) Spraying with coal tar or creosote.

(d) Conversion of B.G. into M.G./N.G. Sleepers–

Broad Gauge wooden sleepers which are classified as unserviceable and removed from track as such can be conveniently converted to serviceable Metre Gauge or Narrow Gauge sleepers whenever their condition permits of such conversions.

Another method is to crop the two ends of the damaged/split sleeper, salvage the middle length to use them for making two block sleepers held together by second

hand tie bars, with two long bolts holding tie bars in each block. The aim should be to obtain maximum life out of sleepers before classifying them as unserviceable. With tamping methods of track maintenance and proper ballast cushion associated with proper treatment of sleepers, the service life of sleepers can be enhanced appreciably.

Dating –

When wooden sleepers are laid, the year of laying should be cut or branded on each sleeper at the centre or one end omitting the first two digits of the century. Thus ‘83’ will indicate that the sleeper was laid in the year ‘1983’. All dates shall

be in one direction, which in the case of double line shall be the direction of traffic and in the case of single line, in the direction of increasing kilometrage. In

the case of ‘U’ category of sleepers the dating will be done at the time of laying and in the case of ‘T’ category sleepers, the dating will be done in the treatment plant before treatment.

Concrete Sleepers

Types of concrete Sleepers

i) Mono-block Pre-stressed Concrete Sleepers.

a) PSC-12 for 52 Kg Rails

b) PSC-14 for 60 Kg Rails

ii) Two block reinforced concrete Sleepers.

Main features of PSC-12/PSC-14 Sleepers:

Length: 2750 mm Weight: 267 Kg

Reinforcement: 18 number 3mm diameter HTS strands

Dist bet. Insert at rail seat: 148mm/162 mm

Service Life: 50 to 60 years.

Advantages of concrete Sleepers:

1. Greater stability.

2. Track geometry maintained for much. longer duration hence economical.

3. Best suited for machine maintenance.

4. Suitable for Track circuiting area.

5. No chances of damage by fire/ corrosion

6. No possibility of theft.

7. No chances of gauge widening.

8. 60 Kg Sleeper can be used for 52 Kg rail.

9. Best suited for LWR track.

10. Best performance on P & C, S.E.J. Guard rails , Level Crossings, Check rail in curve.

Disadvantage:

1. Handling and laying is difficult being heavy.

2. Damage is very heavy in case of derailment.

3. No scrap value.

4. Not suitable for manual packing.

Annual Programme of maintenance of PRC track

The annual maintenance programme for machine maintained concrete sleeper track would be as under:-

Note:

1. For maintenance schedule on LWR track, special instructions in the LWR Manual should, in addition, be followed.

2. Spot renewal of rails and sleepers shall be done as per requirement any time of

the year.

3. Destressing of LWRs shall be done as per requirement and schedule to be prepared by the PWI, as per provisions of LWR Manual.

4. Main tamping, pre and post tamping works shall be done as per schedule of working of the tamper. PWI and AEN should be advised at least one month in advance of the programme of the machine to enable them to complete pretamping operations.

5. Lubrication of ERCs shall be done by Key man throughout the year as per schedule.

6. Oiling and greasing and visual inspection of fish plated joints shall be done.

Fan Shaped Turn-out on Concrete Sleeper.

Ensure the availability of all fittings at site strictly as per requirement of latest drawings for switch portion, lead and crossing portion. The complete turnout will be assembled on a level ground adjacent to the site of laying or on the loop line

connected to turnout. Red/blue rounded marking on the sleepers should invariably be kept on the right hand side irrespective of left hand or right hand turnout. Spacing of sleepers should be strictly as per layout drawing. The sleepers shall be perpendicular to the straight track in switch portion only. In lead portion, the sleepers will be inclined at half the angle between the normal to straight and curved track at that point. Proposed disposition is appended.

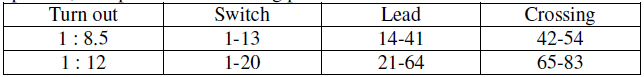

To ensure correct layout, laying of sleeper falling at transition from switch to lead and lead to crossing portion should be paid special attention. Sleepers in the switch portion, lead portion and crossing portion are as under:-

The spacing of the sleepers in the lead portion should be as per layout drawing to

make a radial or fan shaped layout. The spacing has been worked out separately for both the rails. This separate spacing on two rails make the layout fan shaped in lead portion.

The sleepers in the crossing portion shall be perpendicular to bisecting line of crossing. Sleeper no. 3 & 4 may be placed for housing motor with the extended portion of sleeper in reverse direction only in circumstances where it cannot be avoided. The approach sleeper in advance of switch portion should be provided without fail, they are for gradual elimination of slope of rail top (1:20). The exit sleepers behind the crossing portion should also be provided for gradual introduction of rail slope (1:20).

Number of sleepers on Turn Outs

1 in 8½ 54 + 5 + 4 + 4 = 67 Nos.

1 in 12 83 + 5 + 4 + 4 = 96 Nos.

Description of Approach Sleepers

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.