Permanent Way is a way where rails are laid on equal distance with same level. These rails are fixed with sleepers with the help of Fittings and Fastenings which laid on the ballast laid on formation.

Qualities of Ideal Permanent Way

1. Maintenance cost of the permanent way should be low.

2. Gauge should be correct.

3. Gradient should within limits.

4. Curvature and Straightness should be correct.

5. Packing of Permanent way should be correct.

Classification of Rail Routes

Classification of Lines –

(1) Broad Gauge - The BG lines have been classified into six groups ‘A’ to ‘E’ On the basis of the future maximum permissible speeds as under-

Group ‘A’ - Speeds upto 160km. /hour:

(i) New Delhi to Howrah – Rajdhani Route (via the Grand Chord and Howrah- urdhwan Chord).

(ii) New Delhi to Mumbai Central (Frontier Mail Route).

(iii) New Delhi to Chennai Central (Grand Trunk Route).

(iv) Howrah – Nagpur-Mumbai CST.

Group ‘B’ - Speeds upto 130 km. /hour:

(i) Allahabad-Katni-Jabalpur-Itarsi-Bhusaval.

(ii) Kalyan-Pune-Daund-Wadi-Secunderabad-Kazipet.

(iii) Kharagpur-Waltair-Vijayawada.

(iv) Wadi-Raichur-Arakkonam-Chennai Central.

(v) Howrah-Bandel-Barddhaman.

(vi) Khanna-Barharwa-Farakka Bridge-Malda Town.

(vii) Sitarampur-Madhupur-Kiul-Patna-Mughal Sarai.

(viii) Kiul-Bhagalpur-Sahibganj-Barharwa.

(ix) Delhi-Panipet-Ambala Cantt. Kalka.

(x) Ambala Cantt.-Ludhiana-Jallandhar-Pathankot.

(xi) Ambala Cantt.- Moradabad-Lucknow-Pratapgarh-Mughul Sarai.

(xii) Arakkonam-Jolarpettai-Salem-Erode-Coimbatore-Ernakulam.

(xiii) Vadodara-Ahmedabad.

(xiv) Jolarpettai-Bangalore.

(xv) Ahmedabad-Ajmer-Jaipur-Bandikui-Rewari-Delhi.

(xvi) Malda Town-Barsoi-New Jalpaiguri.

(xvii) Chennai Beach-Dindigul.

(xviii) Bangalore-Dharmavaram-Gooty.

(xix) Ghaziabad-Saharanpur.

(xx) Chennai Beach-Chennai Egmore 3rd line

(xxi) Bandikui-Agra Fort

(xxii) Sawaimadhopur-Jaipur

(xxiii) Bellary-Guntkal

(xxiv) Gudur-Renigunta

(xxv) Pagadipalli-Nadikudi-Guntur-Tenali

(xxvi) Vijaywada-Guduwada-Bhimavaram-Nidadavolu

(xxvii) Guntkal-Guntur & Guntur-Krishna canal

(xxviii) Manmad-Mudkhed-Secundrabad

(xxix) Secundrabad-Dhone

(xxx) Renigunta-Tirupati-Pakala-katpadi

Group ‘C’ - Suburban Sections of Mumbai, Delhi, Chennai and Kolkatta as listedbelow.

(i) CSTM – Ravli - Kurla – Panvel

(ii) Ravali –Mahim-Andheri

(iii) Churchgate – Mumbai Central – Borivali- Virar

(iv) Chennai Central – Basin Bridge – Veysarpadi – Arakonam

(v) Dum Dum Jn – Barasat Jn-Bangaon Jn

(vi) Howrah – Panskura – Kharagpur

(vii) Palval-Okhla-Tilak Bridge

(viii) Okhla-LPNR-DBSI, DLI-DKZ-DBSI-NDAZ

(ix) SBB-DSA-DLI

There are 30 routes in Indian railways. (As per correction slip No. 109 of IRPWM)

Group ‘D’ Spl.- Speeds upto 110 kmph and the annual traffic density is 20 GMT or more.

Group ‘D’- Speeds upto 110 kmph and the annual traffic density is less than 20GMT.

Note - While classifying route, in case of double and multiple lines, annual traffic density on each line shall be considered separately. The route shall be classified based on the highest GMT on any one line.

There are 102 D- spl and D routes based speed and GMT. (As per correction slip No. 109 of IRPWM)

Group ’E’ - All other Sections and branch lines with speed upto 100 kmph.

RAILS

Rails are similar to steel girders; these are placed end to end to provide continuous and level surface for the movement of trains.

Functions of Rails

1. The rails provide continuous and level surface for movement of trains.

2. The rails provide a pathway which is smooth and has very less friction. The friction between steel wheel and steel rail is about 1/5th of the friction between the pneumatic tyre and metalled road.

3. The rails serve as a lateral guide for running of wheels.

4. The rails bear the stresses developed due to vertical load transmitted to it through axles and wheels of rolling stock as well as due to braking forces and thermal stresses.

5. The rails carry out the function of transmitting the load to a large area of

formation through sleepers and ballast.

Types of Rails:

1. Double Headed Rail or dumb Bell Section.

2. Bull Headed Rail.

3. Flat Footed Rail or Vignol Rail

Components of Rails:

Following are the components of rails:

1. Head:The head of the rail should have adequate depth to allow for vertical wear.

The rail head should also be sufficiently wide so that not only wider running surface available but the rails has the desired lateral

2. Web:The web should be sufficiently thick so as to with stand the stresses due to the loads coming on it after allowing for normal corrosion.

3. Flange:The flange should be of sufficient thickness so as to with-stand vertical

and horizontal forces after allowing for loss due to corrosion. The flange should

be wide enough so as to be stable against over turning. The design of flange

should be such that it can be economically and efficiently rolled.

Requirements for an Ideal rail section

Following are the ideal requirements of rail section:

1. The rail should have most economical section consistent with strength, stiffness and durability.

2. The centre of gravity of rail sections should preferably be very near to the centre of height of rail so that maximum tensile and compressive stresses are equal.

3. The height of the rail should be adequate so as to have sufficient vertical stiffness and strength as a beam.

4. Standard length of free rail for B.G. is 13 m and for M.G. and N.G. is 12m.

Standard Sections of Rails – ( as per cs no. 117 dated 19/05/09)

( 1 ) General - Rail sections are normally selected to suit the standard of loading and the speeds.

( 2 ) Broad gauge. - The following rail sections should be provided during renewals, construction of new lines, Gauge conversions and Doublings as per the details shown in the ensuing table.

Note : Minimum UTS of rails for sections mentioned above shall be 90 UTS.

Loop Lines : 60 kg ( SH ) or 52 kg ( SH ) should be used. New rails may be used on loop lines of Group A, B & C routes with prior approval of Board.

Sidings :

The rail is designated by its weight per unit length. In F.P.S. unit, it is the weight in pounds per yard and in metric units its weight is in Kg/m. A 52 Kg/m rail denotes that the weight of 1m rail is 52 Kg.

Rolling Marks:

Every rail rolled has a brand on its web, which is repeated at intervals such as:

1. IR-90R-TISCO-II 1995-B.B

• Where IR- Indian Railway

• 90R- Weight and type of section.

• TISCO- Tata Iron and Steel Company

• II1995- Month and year of manufacture.

• B.B- Basic Bassemer Process of Manufacture.

2. IRS-52Kg-710-TISCO-II 1991-O.B.

• Where IRS- Indian Railway Standard

• 52Kg- Type and weight of Rail

• 710- Ultimate Tensile Strength (710 N/mm²)

• TISCO- Tata Iron and Steel Company

• II 1991- Month and Year of Manufacture.

• O.B- Process of manufacture.

The brand marks on the rails shall be rolled in letters at least 20mm in size and

1.5mm in height at intervals of 1.5-3.9 meters.

Weight of Rail and its relation to Axle load:

Though the weight of the rail and its section depends upon the various considerations yet the heaviest axle load on which the rail has to carry plays the most important role. The following is the THUMB RULE for calculating the maximum load with relation to rail section.

Maximum Axle Load = 560 X sectional weight of rail in lbs./yard.

= 510 X sectional weight of rail in Kg/m

Maximum Axle Load = 560 X 90 = 50400 pounds

= 22.5 T

Maximum Axle Load = 510 X 52 = 26520 Kg

= 26.52 T

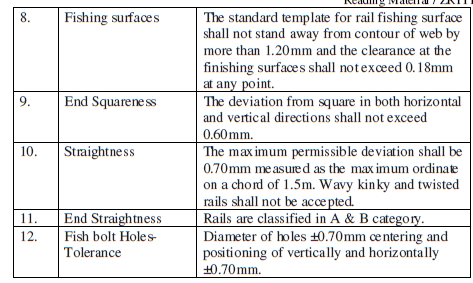

Specifications

Specification for Rails: ( as per cs no.117 dated 19/05/09)

(1) ‘Prime Quality’ Rails. - Indian Railway Specification IRS – T – 12 / 2009

provides the detailed specification of flat bottom rails 68 Kg / m, ZU – 1 – 60 & 52 Kg / m of grade 880 MPa, 1080 MPa CR 1080 MPa HH. These rails shall be

classified as Class ‘A’ and Class ‘B’ rails based on tolerance in End straightness.

This specification also specifies the requirements of special class of rail steel such as Niobium ( NB ), Vanadium ( VN ), Corrosion Resistant rail steel Copper

Molybdenum ( CM ) , Nickel Chromium Copper ( NC ). The rolling mark on rails shall indicate rail section, the grade of steel, identification marks of the manufacturer, process of steel making and direction of rolling of rails.

(2) ‘Industrial Use’ Rails ( IU Rails ) – In addition to above ‘Industrial Use’ rails are arising at steel plants, particularly during the inspection of rails as per IRS – T – 12 2009 while producing ‘Prime Quality Rails. There is no deviation in chemical composition or mechanical properties in “industrial Use Rails from that of Prime Quality rails. The deviations exist only in tolerances for parameters as mentioned in IRS – T – 12 / 2009. These rails can be used in industrial sidings with speed restriction of 50 Kmph. IU rails shall be identified by blue paint on both sides end face of flange on either side for distance of 500 mm from each end. The letter ‘IU’ ( Industrial Use Grade ) shall be stamped in 15 mm size on both end faces of rails in addition to colour marking.

90 U.T.S Rail

Grade 710 710 N/mm² 710/9.8 = 72 Kg/mm²

72 Kg/mm² = 72 UTS (Ultimate Tensile Strength)

Grade 880 880 N/mm²

880/9.8 = 90 kg/mm² 90 U.T.S. (Ultimate Tensile Strength)

Advantages of 90 UTS Rails

1. The service life of the 90 UTS rail is about 50% higher than of conventional manganese rails having 72 UTS

2. The Total GMT which 90UTS can during their primary service life rails are as follow:-

3. 90UTS rails have much superior wear characteristic having hardness of about 270 BHN as against 220 BHN of medium manganese rails with 72 UTS.

4. Allowable shear stress of 90 UTS is much higher as can be seen from comparative figures given below:-

For all such routes where BOX ‘N’ wagons are running, it is desirable to have

90 UTS rails

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.