GENERAL CONSIDERATIONS FOR LAYING LWR/CWR

As a rule, complete track renewals (primary) shall provide for LWR/CWR wherever permissible by the provisions of this Manual. Also existing rails on permitted locations may be converted in to LWR/CWR, provided they meet the requirements laid down in the Manuals for Welding of Rail Joints by Alumino Thermic (SKV process)/Gas Pressure/Flash putt Process, as the case may be.

New constructions/doublings/gauge conversions/retired alignment/permanent diversion shall be opened with LWR/CWR, wherever permissible by the provisions of this Manual.

In goods running lines, goods yards, reception yards and classification yards, rail

joints may be welded to form LWR if the condition of all the components of track is generally sound and without any deficiency, subject to such relaxation as may be approved by Chief Engineer, in each specific case.

ALIGNMENT (As per CS.No 11)

LWR/CWR shall not be laid on' curves sharper than 440 metre radius both for BG and MG. However in temperature zone 1 LWR/CWR may be laid on curves upto 360m radius (5º curve) on B.G. with following additional precautions.

1. Minimum track structure should be 52kg rail on PSC sleeper M+7 sleeper density with 300mm clean ballast cushion.

2. Shoulder ballast for curves sharper than 440m radius should be increased to 600mm on outside of curve and should be provided for 100m beyond the tangent point.

3. Reference mark should be provided at every 50m interval to record creep if any.

4. Each curve of length greater than 250m should preferably be provided with SEJ on either side. SEJ should be located in straight track at 100m away from the tangent point.

LWR/CWR may be continued through reverse curves not sharper than 875 metre radius. For reverse curves sharper than 1500 metre radius, shoulder ballast of 600

mm over a length of 100 metre on either side of the common point should be provided.

GRADIENTS

The steepest permitted grade shall be l: 100.

A vertical curve shall be provided at the junction of the grade when the algebraic difference between the grades is equal to or -more-'than 4 mm per metre or 0.4 percent, as laid down.

The minimum radius of the vertical curve shall be kept as under:

Installation of LWR/CWR or change in its constitution at a later stage shall have the approval of the Territorial Chief Engineer concerned in each case, on a detailed plan prepared. However, for any deviation from the provisions of this Manual, the approval of Chief Engineer shall be obtained

TRACK STRUCTURE FOR LWR/CWR

FORMATION

LWR/CWR shall be laid on stable formation. Formation width shall be conforming to the extant instructions.

BALLAST CUSHION AND SECTION: The minimum clean stone ballast cushion (below the bottom of the sleeper) of 250 mm shall be provided at the time of installation of LWR/CWR. Where speeds in excess of 130 km/h on BG or 100 km/h on MG are to be introduced, at least 300 mm ballast cushion or 200 mm ballast cushion over 150 mm of sub-ballast shall be provided. The ballast section and cushion provided for LWR/CWR shall be continued over SEJ and up to 3 rails beyond it wherever it is followed by SWR/ fish plated track.

SLEEPERS & FASTENINGS

Following types of sleepers and fastenings are approved for use in LWR/CWR:

On Broad Gauge

i) Concrete sleepers with elastic fastenings.

ii) Steel trough sleepers with elastic fastenings for speeds not exceeding 130 km/h. (as an interim measure speed up to 160 km/h may be allowed)

Notes:

a) LWR/CWR already existing on steel trough sleepers and CST-9 sleepers with key fastenings for speeds up to 130 km/h, on BG, if behaving satisfactorily, may be continued.

b) On steel trough sleepers with key fastenings, the breathing lengths' shall preferably be provided with elastic fastenings.

c) In case of CST - 9 sleepers, precautions as indicated in Annexure- II shall be adhered to.

d) Existing LWRs/CWR on wooden sleepers with anticreep bearing (ACB) plates & two way keys or elastic fastenings, if behaving satisfactorily, may be continued for maximum speed of 130 km/h on BG and T00 km/h on MG.

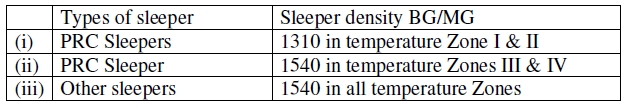

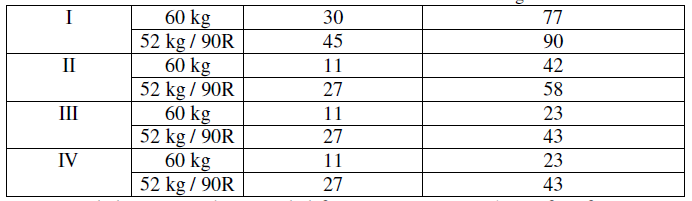

Sleeper density

The minimum sleeper density (number of sleepers laid) in LWR/CWR shall be as

follows:

RAILS

Rails of the following sections shall be welded into LWR/CWR.

LWR/CWR already laid with 60R rails on MG may be allowed to continue.-

• In one LWR, two different rail sections are not permitted. In case of any change in rail section, LWR should be isolated by providing SEJ" (ACS No. 5 of 1999)

• In case of LWRs laid on concrete sleepers having different rail section on either sides SEJs instead of providing three rail lengths of each rail section between SEJs, two 3 rail panels one of each rail sections shall be provided with combination fish plated joints between the two panels (ACS No. 9 of 1999)

• Rail ends, which are bent, hogged, battered, or having history of bolt hole cracks shall be cropped before welding for conversion into LWR/CWR. New rails used in LWR/CWR shall, as far as possible be without fish-bolt holes. Joining of rail ends temporarily during installation of LWR/CWR shall be done by 1 metre long fish plates with special screw clamps /joggled fish plates having slotted grooves & bolted clamps as in figure 4.4.3 (a), (b) & (c) with speed restrictions indicated in Annexure -III. Fish bolt: holes, if any, shall be chamfered.

MISCELLANEOUS

4.5.1 continuity of track structures: Wherever LWR/CWR is followed by fish plated track SWR the same track structure as that of LWR/CWR shall be continued for three rail lengths beyond SEJ.

Level crossings: Level crossings situated in LWR/CWR territory shall not fall within the breathing lengths.

Points and Crossings LWR/CWR shall not normally be taken through points and

crossings. Three normal rail lengths shall be provided between stock rail joint (SEJ) and SEJ as well as between the crossing and SEJ. These normal rail lengths shall be provided with elastic rail clips /anchors to arrest creep. ‘’However, where concrete sleeper turnouts are laid, instead of three normal rail lengths, one three rail panel shall be provided between SEJ as well as between heel of crossing and SEJ’’. (ACS No. 8 of 2002)

LWR/CWR shall not be taken through points & crossings. For any exceptions in these regards, special- arrangements shall have the prior approval of RDSO.

Glued Joints: All insulations for track circuiting in LWR/CWR shall be done by

providing glued joints G3 (L) type.

Location of SEJ: The exact location of SEJ shall be fixed taking into account the

location of various obligatory paints such as level crossings, girder bridges, points and crossings gradients, curves and insulated joints. SEJ with straight tongue and stock shall not be located on curves sharper than 0.5 degree (3500 m radius) as far as possible. SEJ shall not be located on transition of curves.

Bridges with ballasted deck (without bearing): LWR/CWR can be continued over

bridges without bearings like slabs, box culverts and arches.

Bridges with/without ballasted deck

(i) LWR/CWR shall not be continued over bridges with overall length as specified in para 4.5.7.1 for BG and. not: more than 20 metre for MG.

(ii) Bridges on which LWR/CWR is not permitted/ provided shall be isolated by a minimum length of 36 metre well anchored track on either sides

(i) Bridges provided with rail - free fastenings (single span not exceeding 30.5 metre and having sliding bearings on both ends.)

Overall length of the bridge should not exceed the maximum as provided in Table-1 with following stipulations.

(a) Rail free fastenings shall be provided throughout the length of the bridge between abutments;

(b) The approach track up to 50 m on both sides shall be well anchored by providing any one of the following: -

i) ST sleepers with elastic fastenings. ii) PRC sleepers with elastic rail clips with fair T or similar type creep anchors.

(c) The ballast section of approach track up to 50 metre shall be heaped up to the foot of the rail on the shoulders and kept in well consolidated & completed condition during the months of extreme summer and winter. 4.5.7.1

(ii) Bridges provided with rail free fastenings and partly box anchored (with single span not exceeding 30.5 metre and having sliding bearings at both ends.) Overall length of the bridge should not exceed the maximum as provided in Table-I with following stipulations.

(a) On each span, 4 central sleepers shall be box anchored with fair V or similar type creep anchors and the remaining sleepers shall be provided with rail-free fastenings.

(b) The bridge timbers laid on girders shall not be provided with through notch but shall be notched to accommodate individual rivet heads.

(c) The track structure in the approaches shall be laid and maintained to the standards as seated.

(d) The girders shall be centralized with reference to the location strips on the

bearing, before laying LWR/CWR.

(e) The sliding bearings shall be inspected during the months of March and October each year and cleared of all foreign material. Lubrication of the bearings shall be done once in two years.

Maximum overall length of bridges permitted on LWR / CWR on B.G. (in

metre).

(iii) Welded rails may be provided from pier to pier with rail-free fastenings and with SEJ on each pier. The-rail shall be box anchored on four sleepers at the fixed end of the; girder if the girder is supported on one side and rockers on other side. In case of girder supported on sliding. Bearings on both sides, the central portion of the welded rails over each span shall be box anchored on four sleepers.

(iv) LWR/CWR may also .be continued over a bridge with the provision of SEJ at the far end approach of the bridge using rail-free fastenings overt the bridge. The length of the bridge in this case, however, will be restricted by the capacity of the SEJ to absorb expansion, contraction and creep, if any, of the rails. The length of the bridges with the above arrangement that can be permitted in various rail temperature zones for LWR/CWR with SEJs having maximum movement of 120 mm and 190 mm are as follows:

(v) Welded rails may be provided over a single span bridge with rail free fastenings and SEJs at 30m away from both abutments. The rail shall be box anchored on 4 sleepers at the fixed end of the bridge if bridge is supported on rollers on one side and rockers on other side. In case of bridge supported on sliding bearings on both sides the central portion of the welded rails shall be box anchored on 4 sleepers. On both side of approaches fully creep anchored fastening shall be used. The length of single span bridge permitted temperature zone wise shall be as under:-

LAYING OF LONG WELDED RAILS AND CONTINUOUS WELDED RAILS

1.Survey 2. Temperature record

3.Material required

4. Preliminary works

5.Welding of rails to form LWR

6.Gaps at SEJ ( 52kg / 60kg = 40mm and Others = 60mm)

7.Destressing of LWR

8. Joining LWRs into CWR

9.Reference mark

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.