1. Regular track maintenance in LWR/CWR includes following operations: (ACS

No. 2 of 1999)

i) Tamping/packing

ii) Lifting iii) Aligning including minor realignment of curves

iv) Shallow screening/shoulder cleaning

v) Renewal of fastening requiring lifting vi) Maintenance of buffer rails

No. 2 of 1999)

i) Tamping/packing

ii) Lifting iii) Aligning including minor realignment of curves

iv) Shallow screening/shoulder cleaning

v) Renewal of fastening requiring lifting vi) Maintenance of buffer rails

2. SPECIAL TRACK MAINTENANCE (ACS No. 4 of 1999)

Special track maintenance in LWR/CWR includes following operations:

i) Through fittings renewal

ii) Deep screening/mechanised cleaning of ballast

iii) Lowering / Lifting of track iv) Major realignment of curves

iii) Lowering / Lifting of track iv) Major realignment of curves

v) Sleeper renewal, other than casual renewals

vi) Rehabilitation of bridges and formation causing disturbance to track

vi) Rehabilitation of bridges and formation causing disturbance to track

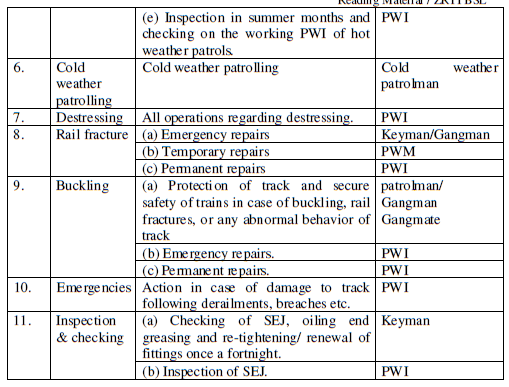

DESTRESSING DURING MAINTENANCE

Abnormal behavior of LWR/CWR whenever gets manifested in one or more of the Following, destressing shall be undertaken as per procedure laid down.

i) When the gap observed at SEJ

(a) differs beyond limits specified by ±10 mm ;

(b) exceeds the maximum designed gap of SEJ;

(c) When corner of stock/ tip of tongue rail crosses the reference line (CS.No 10).

ii) After special maintenance operations mentioned.

iii) After restoration of track following an unusual occurrence mentioned.

iv) If number of locations where temporary repairs have been done exceed three per km.

Destressing of CWR shall be done by cutting it into LWRs of about 1 km length,

which shall be joined after destressing in accordance.

Procedure for repairs

If any fracture takes place on LWR/CWR, immediate action shall be taken by the

official who detected the fracture to suspend the traffic and to protect the line. He

shall report the fracture to the Gangmate Keyman/PWI, who shall arrange for making emergency repairs to pass the traffic immediately. Repairs shall be carried out in four stages as described below

1. Emergency repairs to pass the traffic immediately: - If the gap at fracture does

not exceed 30 mm, insertion of any closure rail niece is not necessary. The traffic

may then be resumed at a speed of stop dead and 10 kmph for the first train and

20 km/h for subsequent trains.

2. Temporary repairs :- If a welding party is not readily available, the fracture shall be repaired by using a cut-rail (not less than 4 metre long) and clamped/bolted.

3. Permanent repairs: - Is carried out using wide gap welding using rail tensor or

by replacing fractured rail by a sound USFD tested rail closure (not less than 4m)

and welding the gap using rail tensor as the situation permit.

4. Destressing:- After welding of joints, a length of track equal to breathing length or about 125 meters on either side be unfastened and tapped to ensure equalization of stress and then refastened.

Repairs to Buckled Track:-

i) When the track actually buckles, the traffic shall be suspended and the cause of

buckling ascertained. The position of tongue and stock rails of the SEJ shall be checked. The methods for rectification are explained below.

ii) The rectification shall normally be carried out in the following stages under the supervision of PWI: -

1. Emergency repairs.

2. Permanent repairs.

3. Destressing.

Deep screening / mechanized cleaning of ballast

i) Provisions laid down will also apply mutatis - mutandis to LWR/CWR with further provisions as mentioned. Wherever mechanized cleaning of ballast is resorted, the detailed procedure laid down for manual deep screening shall stand replaced by the sequence of operations of Ballast Cleaning Machine (BCM).

ii) Ballast Cleaning Machine (BCM), tamping machine and Dynamic Track Stabilizer (DTS) shall, as far as possible, be deployed in one consist.

iii) Temperature records of the sections where deep screening is to be undertaken, shall be studied for the previous and the current year. The maximum and minimum rail temperature attainable during the period of deep screening and

during the period of consolidation shall be estimated. Any of the following three methods may be adopted for Carrying out the work of deep screening/mechanised cleaning:

a) If range of rail temperature falls within td + 10ᴼ C to td + 20ᴼ C. Deep screening may be done without cutting or temporary destressing.

b) If range of rail temperature falls outside (a) above, Temporary destressing shall be carried out 10ᴼ C below the maximum rail temperature likely to be attained during the period of work. CWR shall be cut into LWRs of about 1 km length with two temporary buffer rails of 6.5 metre long clamped as per arrangements shown.

c) Wherever rail renewals are being carried out, LWR/CWR may be converted into three rail panels and deep screening done.

iv) Constant monitoring of rail temperature shall be done during the progress of work. Should the temperature rise more than 10ᴼ C above td /temporary destressing temperature, adequate precautions shall be taken including another round of temporary destressing.

Note: Deep screening shall be under taken within 15 days of temporary destressing failing which temporary destressing may become due again, if the range of rail temperature varies appreciably.

v) During the period of deep screening, if there is any possibility of minimum temperature falling 30ᴼ C below td/temporary destressing temperature, cold weather patrol should be should be introduced to detect/ guard against rail

fractures.

vi) Sequence of operation: -

a) Deep screening of LWR may be done from one end of LWR to other end.

b) After deep screening and consolidation of track, destressing of LWR shall be

undertaken.

Note: Hot end Cold Weather Patrolmen should be aware of their duties and should be drawn, as far as Possible, from gangs.

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.