Protection of rail from liner biting.

Ans. Protection of rail from liner biting-

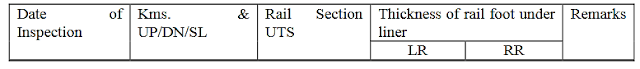

Generally in yards due to drainage problem, which causes dampness conditions, there is corrosion mainly in the rail foot area. In addition in stretches where passenger trains run in the early morning hours, due to toilet droppings, there is reduction in the rail foot in the area which is in contact with the liners. The remaining section of the rail is normally not affected in such cases. In case of rail corrosion at fastening location, the measurement of rail corrosion in rail foot it to be done at every 500mm or part once a year. The format for this measurement shall be as given below :-

Rail corrosion at fastening location –

1. To minimise the occurrence of this problem, as a preventive measure, at the time of initial provision as well at the time of periodic cleaning of central leg of elastic rail clips.

Graphite grease grade ‘O’ to IS:408 shall be applied on the underside of liners as well as moisture to the surface of the liner and rail foot, grease shall be applied along the boundary of liner to seal the liner boundary. In areas indentified to the prone to such corrosion. This treatment shall be done once a year and in other sections with concrete sleepers once in two years.

2. In case of location identified to be prone to corrosion, shifting of rail from its position will result into stopping of further development of corrosion at same location and will result into increase in life. By shifting of rail from its posisition, the reduced foot section due to corrosion gets shifted away from the liner. Thus, its further reduction in foot thickness at same location due to corrosion gets eliminated and new location with normal thickness comes under the liner to accept further corrosion. Thus the reduction of foot thickness at one location gets stopped. This is to be done when the rail is relatively new and reduction in rail foot area is less i.e. reduction in rail foot is less then 1.5mm. This may be done by de-stressing.

3. As this type of corrosion is observed more on gauge face side, changing/turning of rail will result into making the gauge face as non gauge face which will result into increase in life of rail as the reduction of foot thickness at same location will get stopped.

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.