Deep Screening of Ballast-

(1) General –

(a) It is essential that track is well drained for which screening of ballast should be carried out periodically as described. Due to presence of bad formation, ballast attrition, excessive rain fall and dropping of ashes and ore, ballast gets choked up and track drainage is impaired. In such situations, it becomes necessary to screen the entire ballast right up to the formation level /sub-ballast level. Further through screening restores the resiliency and elasticity of the ballast bed, resulting in improved running quality of track. Such screening is called “Deep screening”, as distinguished from the shallow screening, which is done, during overhauling.

(b) Deep screening should be carried out in the following situations by providing full ballast cushion:

(1) Prior to complete track renewal.

(2) Prior to through sleeper renewal.

(3) Where the caking of ballast has resulted in unsatisfactory riding.

(4) Before converting existing track, fish plated or SWR into LWR or CWR; or before introduction of machine maintenance, unless the ballast was screened in recent past.

(5) The entire track must be deep screened atleast once in ten years.

(c) The need for intermediate screening between track renewals may be decided by the Chief Engineer depending on the local conditions.

(d) At the time of deep screening, standard ballast section should be provided invariably.

(e) In case of the bad formation, formation treatment should be carried out along with the deep screening.

(f) The work of deep screening should be carried out continuously from one end of the section to the other.

(2) Procedure for systematic Deep screening (not applicable to LWR S sections) –

(a) Survey:

Before deep screening of a section is undertaken, it is necessary to survey the section. This will consist of the following operations :

(i) A longitudinal section of the track should be taken indicating the rail levels at every 30 meters, as also at changes of the grades, obligatory points like culverts, bridges, over line structures, tunnels, level crossings, Signal gantries, ash pits, and points and crossings etc.

(ii) In station yards, on run through lines, cross sections at every 50 meters should be taken and plotted including platform levels, rail levels and clearance to underside of over line structures.

(iii) On the basis of longitudinal and cross sections, the final levels will be decided by the

(a)Divisional Engineer, keeping in view - The depth of ballast cushion to be provided; The relative implications of lifting or lowering of track; The possibility of eliminating humps, sags, and unevenness in the existing longitudinal section. It is not necessarily the intention that the original longitudinal section of the line should be restored.

(a)Divisional Engineer, keeping in view - The depth of ballast cushion to be provided; The relative implications of lifting or lowering of track; The possibility of eliminating humps, sags, and unevenness in the existing longitudinal section. It is not necessarily the intention that the original longitudinal section of the line should be restored.

(b) Preparation of Estimates – The estimate for the work of deep screening and full ballasting should also include provision of survey mentioned.

(c) Preliminary works. –

(i) Additional ballast required, should be unloaded/spread out opposite to the place where it is required. When ballast is collected along the track, care should be taken to see that the new ballast is not mixed with the unscreened ballast .

(ii) Cess should be brought up to correct level in relation to the final rail level.

(iii) Pegs should be provided at intervals of 30 metres to indicate the final rail levels.

(iv) Slewing of curves should be done in advance.

(v) Sleeper renewal as necessary should be carried out in advance.

(d) Screening operations - General –

(i) The work would be done under the supervision of an official not lower in rank

than the Permanent Way Inspector Grade III.

(ii) The daily output should be pre-determined, depending on the time allowance,

availability of labour, extent of ballasting/screening to be done etc.

(iii) Taking the length to be deep screened daily, planning of speed restriction should be done and necessary notice should be issued to all concerned and speed

restriction boards put up.

(iv) It will be desirable to proceed with the work of deep screening in the direction opposite to that of the traffic on double line.

(e) Detailed procedure – A day’s length will be deep screened as per the procedure detailed below:

Stage I The ballast should be removed from space ‘A’ and ‘B’ on either side of the sleeper ‘1’ down to final formation level and wooden blocks provided to support the rail for passing trains.

Stage II The ballast is removed from under sleeper ‘1’ down to final formation level/sub-ballast level.

Stage III The ballast should then be screened and placed back under sleeper ‘1’ which should then be packed.

Stage IV The wooden blocks from space ‘A’ should then be removed.

Stage V The ballast from space ‘C’ down to formation level should be removed and after screening, be placed in space ‘A’ upto bottom of sleeper .The balance may be taken outside the track and screened .The rail in space ‘C’ should be supported with wooden blocks.

Stage VI The ballast should be removed from under sleeper ‘2’ down to formation level.

Stage VII Screened ballast should be provided under sleeper ‘2’ and sleeper well

packed.

Stage VIII The ballast from space ‘D’ down to formation level should be removed and after screening, be placed in space ‘B’ upto bottom of sleeper; the balance may be taken outside the track and screened. The wooden blocks should be removed from space ‘B’ and placed to support the rail in space ‘D’.

Stage IX The ballast from under sleeper ‘3’ should be removed and so on till the

whole rail length is provided with screened ballast upto level of the bottom of sleepers.

Final Stage The track should be lifted to provide additional cushion where required.

The track should be packed in the final position and then boxed.

Sequence of the operations is shown in the sketch:

The following points may be kept in view while doing the work –

1. No unscreened length should be left between screened lengths of the track at the same time.

2. It should be ensured, that when ballast is being removed from any sleeper, invariably, there are at least four fully supported sleepers between it and the next sleeper worked upon.

3. Lifting should be limited to 50 mm. at a time.

4. It should be ensured that packing, cross levels and grade run off are satisfactory before closing the day’s work.

5. The work should be done under a speed restriction of 20 km.p.h.

6. The speed should be gradually raised below which will vary depending on the

type of maintenance in the section.

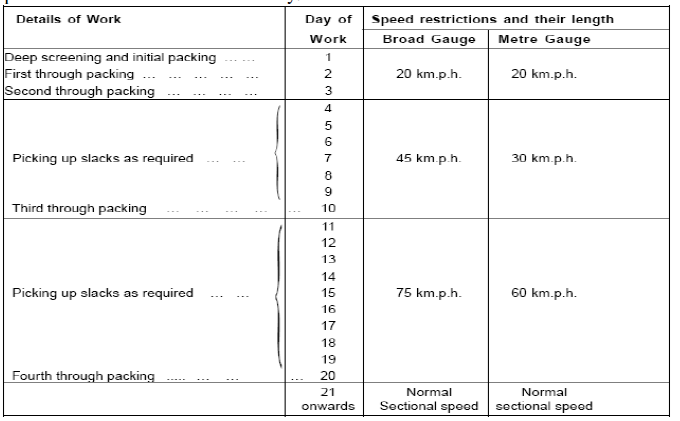

7. Schedule for working and speed restriction to be observed in deep screening works.

With Manual Packing –

The details of the work to be carried out in stages on various days, after the starting of the screening operation and the speed restriction recommended to be imposed are shown in Table 1. According to the above schedule normal Sectional

speed can be resorted on the 21st day.

With Machine Packing –

The details of work to be carried out in stages on various days after the start of the screening operations and the speed restriction recommended to be imposed are indicated in the schematic representation in Table II. According to this schedule, normal sectional speed can be resumed on the tenth day.

The period mentioned in the schedules shown above is the minimum and can be

suitably increased to suit local condition of the track consolidation.

Deep Screening by BCM – (as per cs no. 122 dated /11/10)

Deep Screening with BCM ( Ballast Cleaning Machine ) and followed by Tamping and Stabilisation of Track with TTM and DTS respectively for BG – The work is to be carried out in stages on various days after the start of the screening operations and the speed restriction recommended to be imposed are indicated in the schematic representation in table below. According to the schedule normal sectional speed can be resumed on the 8th day.

Schedule of speed restriction for deep screening by BCM followed by Tamping

and Stabilisation by TTM and DTS machines for BG

The period of the schedule shown above can be suitably increased to suit local conditions of the track consolidation.

Precaution to be taken during deep screening of track by BCM followed by TTM and DTS machines :

( i ) All precautions laid down in LWR manual ( specially those in para no. 6.3.2)

shall be strictly followed.

( ii ) Hard Sal wood blocks of size 600 x 300 x 300 mm ( six numbers ) duly end

bounded shall be arranged for supporting ends of three adjoining sleepers where cutter bar is left in the track and remains untamped.

( iii ) Sleepers of cutter bar area shall be manually packed and ballast under cutter bar location sleepers shall be removed only half an hour before the expected traffic block. Adequate care shall be taken to ensure that wooden blocks are not dislodged before arrival of BCM at site.

( iv ) Fish plated joint shall not be located in cutter bar location.

( v ) Ramp shall not be located in locations like level crossing, girder bridge, transition portion of curve etc. It shall be kept minimum two rail length away.

( vi ) In case of fracture or cut in CWR / LWR, a speed restriction of 20 Kmph shall be imposed till it is repaired as per para 7.2.3 of LWR Manual.

( vii ) In case of malfunctioning of TTM and or DTS, deep screening shall be stopped and track which has not been tamped and stabilized shall be attended manually by ballast ramming and correction of track geometry to ensure safety of running trains. Speed restriction shall be imposed and relaxed in term of IRPWM para 238 ( 2 ) ( g ) ( i ) or ( ii ) which ever is the case.

( viii ) In case of non availability of traffic block on subsequent days of deep screening by BCM speed restriction shall be imposed and relaxed in term of IRPWM para 238 ( 2 ) ( g ) ( i ) or ( ii ) which ever is the case.

( ix ) When BRM is not deployed, adequate track men shall be deputed to recoup

ballast, particularly in shoulder and maintain ballast profile after machine working.

( x ) Lifting of track shall be resorted after ensuring adequate availability of ballast for maintaining ballast profile for planned lifting.

( xi ) Adequate arrangements for supply and training out of ballast prior to deep

screening should be made. Special care shall be taken by deploying watchman on

stretches overdue for rail renewal.

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.