Criteria for rail renewal-

The following are to be considered in connection with the criteria of rail renewals:-

•Incidence of rail fracture / failures.

•Wear on rails.

•Maintainability of track to prescribed standards.

•Expected service life in terms of Gross million tones carried.

(a) Incidence of Rail fractures/failures – A spate of rail fractures on a particular sections having 5 withdrawals of rails per 10 km. in a year due to fracture and / or rail flows defected ultrasonically falling in the category of IMR will have priority while deciding rail renewals. In case the rail failures at fish plated/ welded joints are pre-dominant, end cropping with or without wilding could be considered. Through Rail Renewal is also allowed in location of track where more than 30 defective welds per track km are existing.

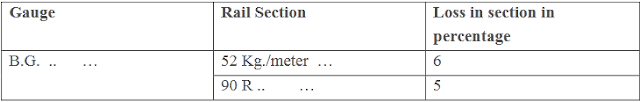

(b) Wear on Rails – (i) Limiting Loss of Section- The limiting loss in rail section, as a criterion for recommending rail renewals shall be as under:

Rail wear may be determined by actual weighment talking rail profiles at ends after unfishing joints and taking rail profiles with special profile measuring gadgets.

(ii) Wear due to corrosion – Corrosion beyond 1.5 mm in the web and foot may be taken as the criterion of wear due to corrosion. Existence of the localized corrosion such as corrosion pits, specially on the underside of the foot and loner biting etc. on rail foot, act as stress raiser for the origin of fatigue cracks and would necessitate renewal.

(iii) vertical wear - when the reduction of the depth of the rail head reaches a point beyond which there is a risk of wheel flanges grazing the fish- plates, such rails should be renewed. The limits of vertical wear a which renewals are too ne planned are given as below.

Vertical wear is to be measured at the centre of the rail either by measuring the height of the worn out rail by calipers or by plotting the profile. In the first case, the wear is the difference between the height of the new rail and the height of the worn out rails.

(iv) Lateral wear – Limits of lateral wear form relaying considerations are as under :

Lateral wear is to be measured a 13 to 15 mm. below the rail top table. Worn rail profile should be recorded and superimposed over new rail profile to find out the lateral wear.

(C) Maintainability OF Track to prescribed standards –

(i) There may be cases, where renewals may be necessary on the following consideration viz.,

(1) Poor running quality of track in spite of extra maintenance labour engaged for maintaining the same,

(2) Disproportionate cost of maintaining the portion of track in safe condition.

(ii) The condition of rails with regard to hogging/battering , scanning and wheel burns and other conditions such as excessive corrugation of rail as can be ascertained by visual inspections, which affects the running quality of track, and make the track maintenance difficult and uneconomical, should be taken into account while proposing renewals.

(iii) Renewals of rail due to hogged and battered rails ends should be considered only if other remedies have not been found to be effective.

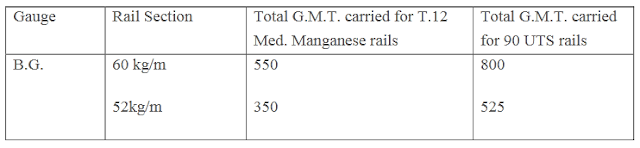

(d) Renewal on consideration of service life in terms of total G.M.T. of traffic carried – The rail shall be planned for through renewal after it has carried the minimum total traffic as shown below:

(e) –The service life in terms of total GMT of traffic carried for considering through rail renewal on the bridge proper and in approaches (upto 100 m on either side ) for all the important bridges and such of the major bridges where height of bank is in excess of 4.m, all tunnels and their approaches (upto 100 m on either side shall be half of the GMT specified.

(f) Plan bassed Renewal – Renewal to pre-determined plan with the objective of modernizing the track structure on selected routes in the quickest possible time may be planned even if it involves premature renewals.

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.